As the coffee industry accelerates its push for sustainability, even the tiniest details—like the ink on your coffee cups—can have a big impact on the environment. Shanghai-based eco-friendly packaging specialist Tongshang is leading the way, offering water-based and plant-based inks for custom cups and sleeves. Here’s why these inks are important and how they can help cafés reduce their carbon footprint without sacrificing a distinct design.

Why traditional inks are not satisfactory

Most traditional printing inks rely on petroleum-derived solvents and heavy metals that can contaminate recycling streams. When cups or sleeves printed with these inks end up in compost or paper mills, harmful residues can leach into the environment or interfere with the paper recycling process. As regulations tighten, especially in Europe and North America, cafes face fines or disposal challenges if their printed materials don’t meet new eco-standards.

Water-based and vegetable-based inks to the rescue

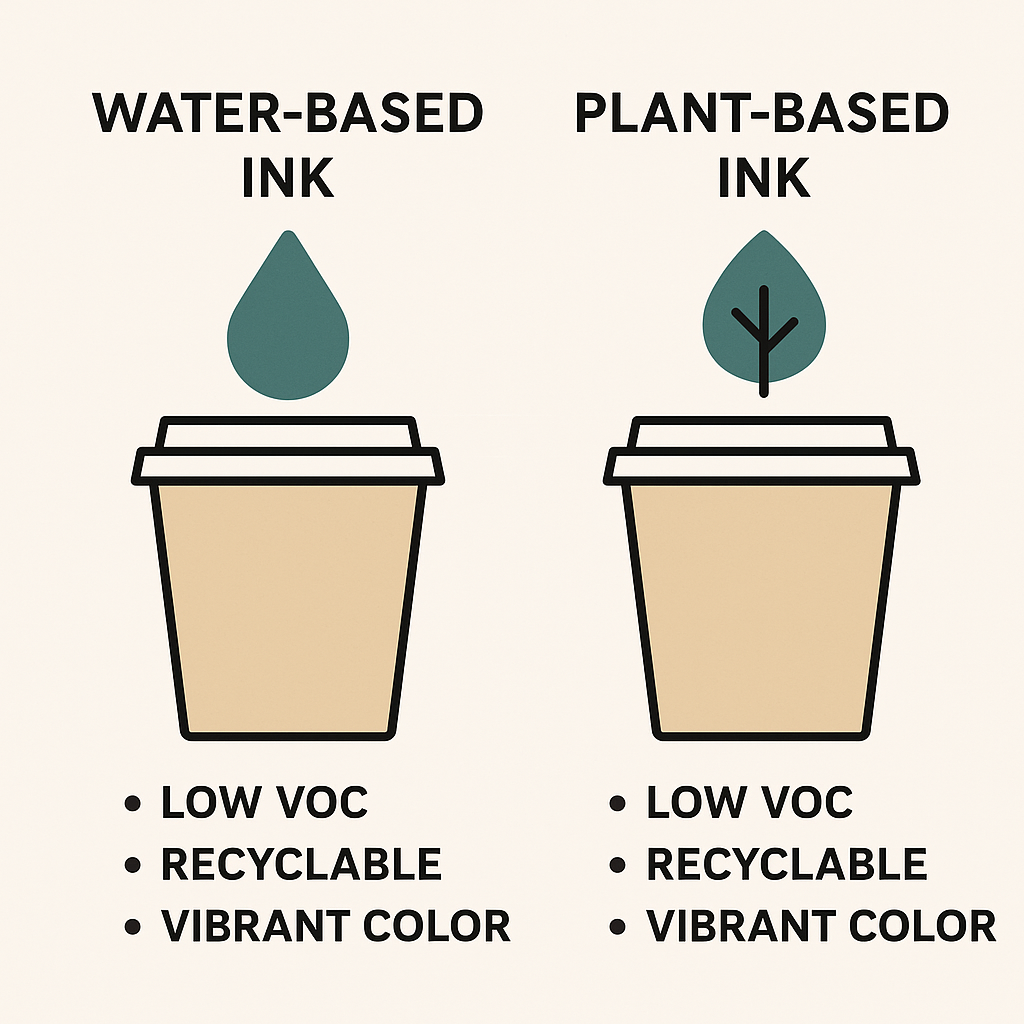

Tonchant’s water-based inks replace harmful solvents with a simple water vehicle, while vegetable-based inks use soybean, canola or castor oil instead of petrochemicals. Both inks offer the following benefits:

Low VOC emissions: Volatile organic compounds are significantly reduced, improving air quality in the printing facility and café.

Easily Recyclable and Compostable: Cups and sleeves printed with these inks can go into standard paper recycling or industrial composting without contaminating the waste stream.

Vibrant, long-lasting colors: Advances in formulation mean that eco-inks can now deliver the same bright, fade-resistant results that coffee brands demand.

Achieving brand and environmental goals

Designers no longer have to choose between beautiful packaging and environmental credentials. Tonchant’s printing team works closely with clients to match Pantone colors, ensure logos are sharp, and even handle complex patterns—all with sustainable ink systems. Short-run digital printing allows independent roasters to test seasonal artwork without wasting large amounts of solvent, while large-volume flexographic printing maintains consistent environmental performance at scale.

Real-world impact

Early adopters of eco-friendly inks have reported a reduction in their waste disposal costs by up to 20% since switching to eco-friendly inks, as their cups and sleeves can now be composted rather than landfilled. A European coffee chain has reprinted its cups with vegetable inks and has been praised by local municipalities for complying with the new single-use plastics directive.

Looking ahead

As more regions implement stricter packaging and paper standards, printing with environmentally friendly inks will become the norm rather than the exception. Tonchant has begun exploring next-generation bio-based pigments and UV-curable formulations to further reduce energy consumption and chemical residues.

Cafes and roasters looking to improve their sustainability can work with Tonchant to switch printing on cups and sleeves to water-based or plant-based inks. The result? A sharper brand image, happier customers, and a truly greener footprint—one cup at a time.

Post time: Jul-29-2025